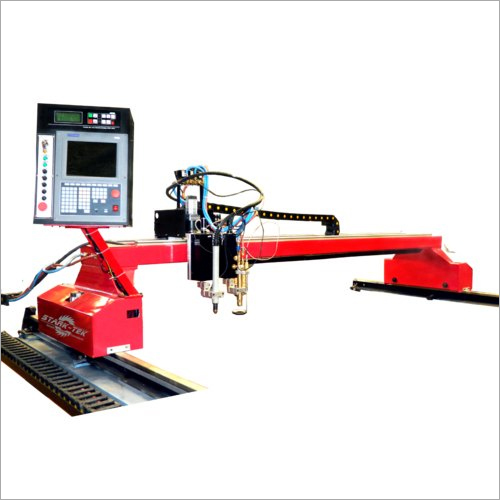

CNC Gas Cutting Machine

Product Details:

CNC Gas Cutting Machine Price And Quantity

- 1150000 INR/Unit

- 1050000.00 - 1550000.00 INR/Unit

- 1 Unit

CNC Gas Cutting Machine Trade Information

- 10-15 Unit Per Month

- 1 Week

Product Description

Specification

| CNC System | SH2200 OR Higher |

| Drive Method | Dual side with AC Servo Digital Motors |

| Height sensor | Capacitive Height sensor |

| Maximum cutting Length (mm) | 3000-8000 |

| Maximum cutting Width (mm) | 1600-3000 |

| Programming Software | Fastcam/Hypertherm |

| Speed (mm/min) | 0 to 10000 |

| Track Precision | +-0.3mm/6m |

| Track repeat Precision | +-0.5mm/6m |

| Weight (Kg) | 400-700 |

| Model | HCZ 1600 X 3000 |

| Automatic Grade | Automatic |

| Brand | Stark-Tek |

FAQ:

Q: What is a CNC gas cutting machine?

A: CNC (Computer Numeric Control) gas cutting machine is a type of cutting machine that uses a gas torch to cut metal. The machine is controlled by a computer program, which allows for precise cutting of complex shapes.

Q: What are the types of gas used in CNC gas cutting machines?

A: The most commonly used gases in CNC gas cutting machines are oxygen and acetylene, propane, natural gas, and hydrogen. The type of gas used depends on the thickness of the material being cut and the desired cutting speed.

Q: What materials can be cut with a CNC gas cutting machine?

A: CNC gas cutting machines can be used to cut a variety of metal materials including steel, aluminum, and stainless steel, among others.

Q: What are the benefits of using a CNC gas cutting machine?

A: The benefits of using CNC gas cutting machine include improved precision, higher cutting speeds, and the ability to cut complex shapes.

Q: How does a CNC gas cutting machine work?

A: CNC gas cutting machine uses a high-temperature gas torch to heat and cut metal. The torch is controlled by a computer program, which allows for precise cutting of complex shapes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'CNC Cutting Machine' category

|

SYSTEM ENGINEERS CUTTING & WELDING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |